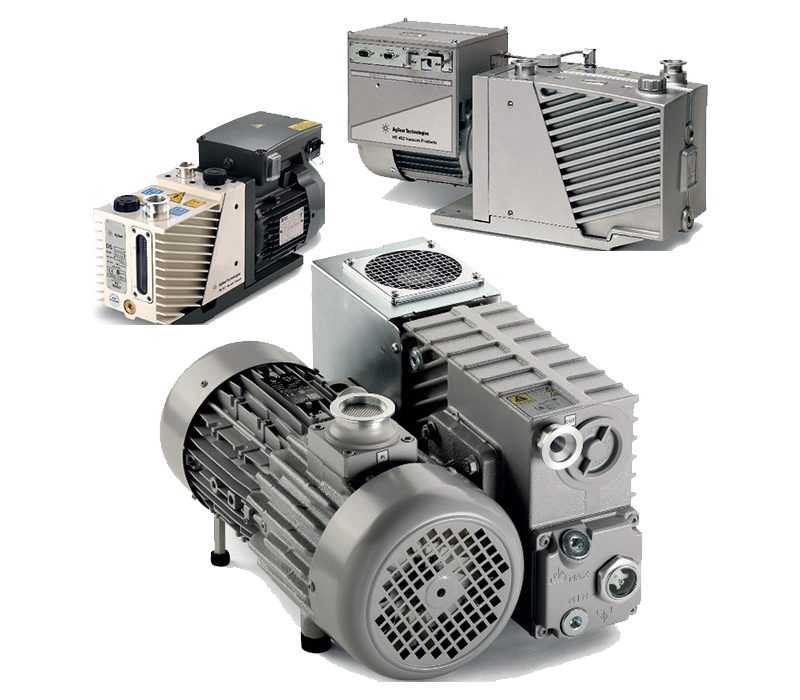

Single and dual stage rotary vane pumps are available in a variety of pumping speeds and configurations. These pumps are ideal backing pumps for turbomolecular or diffusion pumps, or stand alone in laboratory, analytical or industrial applications.

DS Series Oil Sealed Rotary Vane Vacuum Pump models are available in pumping speeds from 45 - 605 L/min (1.6 - 21.4 cfm) and ultimate pressures < 2 x 10E-03 mbar. The DS series pumps operate at a very low noise level.

The high-capacity single-stage oil-lubricated rotary vane pumps of the MS series are an ideal alternative to larger industrial pumps with similar pumping speeds, being compact and environmentally friendly. The flexible MS series pumps feature robust and reliable components, high pumping speeds at low pressures, low noise levels and easy installation.

DS 102 Rotary Vane Pump

The DS 102 is a two-stage oil-sealed rotary vane pump capable of pumping speeds up to 5.0 m 3 /h at 50 hz and 3.5 CFM at 60 hz and capable of ultimate pressures < 2 x 10 -3 mbar . The DS 102 uses a universal voltage single phase motor with an integrated mains switch.

A suction port isolating valve integrated into the pump closes the suction port in the event of a power interruption to the pump. The anti-suckback valve maintains the vacuum in the backing pump and prevents pump oil from contaminating the vacuum chamber. The DS 102 is equipped with a manual gas ballast valve which, when open, allows the pump to be rated for water vapor handling.

characteristic

Dual-stage design enables working pressures down to 10 -3 mbar and low operating temperatures with minimal oil flooding at low pressures, while providing good pumping rates and gas ballast effects in the low pressure range of 10 -2 mbar

Single-phase or three-phase motors are available worldwide for all voltages and frequencies. Easy selection of operating voltage provides greater flexibility, facilitates planning and reduces inventory

Anti-suckback valve and blowdown device isolates the pump when it is out of service or idle, while preventing improper blowdown of the vacuum system and pump oil contamination in the event of a pump shutdown or power failure

Socket type IEC320 allows standard power cords to be used without opening the box cover to wire the motor

With the gas ballast valve open, dry air is injected into the second stage of the pump, this action heats up the module, which helps vent and remove water vapor or other condensable gases from the pump oil

MS40+ Rotary Vane Pump

The MS40+ is the ideal backing pump for LC/MS and ICP-MS instruments. The MS40+ single-stage oil-sealed rotary vane pump offers high pumping speed (40 m 3 /h) in a compact size. This pump is equipped with an integrated exhaust/pump oil filtration system with replaceable exhaust port filter elements. This makes the pump suitable for high gas throughput operating conditions, achieving ultimate pressures < 5 -2 mbar.

Agilent offers the MS40+ pump with a choice of speeds ranging from 1200 rpm to 1620 rpm. See the catalog number for each model for corresponding specifications.

characteristic

High suction volume, small size

Variable frequency drive motor adjusts pumping speed and pressure and reduces power consumption

High pressure stability in the 10 -2 mbar pressure range

AVF Gold and Platinum pump oils available

Pump models with different speeds available

MS-101 Rotary Vane Pump

The Agilent MS-101 is a high capacity single stage oil lubricated rotary vane pump. The MS-101 features an oil circulation system, an anti-suckback valve to prevent system contamination, and carbon fiber composite vanes to extend pump life. With its low vibration performance and air-cooled system, MS-101 is an excellent alternative to large industrial pumps with similar pumping speed but high noise and vibration and high maintenance costs. It is powerful, compact and environmentally friendly.

Our highly reliable MS-101 pumps are commonly used in conjunction with diffusion HV pumps in a variety of industrial applications including metallurgy, heat treating, vacuum coating, electron beam welding, helium leak detection, and liquefied natural gas (LNG) transportation, among others.

characteristic

Industry-leading vacuum performance with ultimate pressures of 8 x 10 -2 mbar (6 x 10 -2 torr)

Highly stable to meet stringent application requirements

Steel rotors with specially designed carbon fiber blades extend pump life and gas ballast valves allow for use in applications with high water vapor content

Compared with pumps with the same pumping speed, the pump is compact and easy to install

Highly reliable performance with highly efficient pump oil circulation system

Integrate built-in mist eliminator system with float valve for pump oil recovery, go green